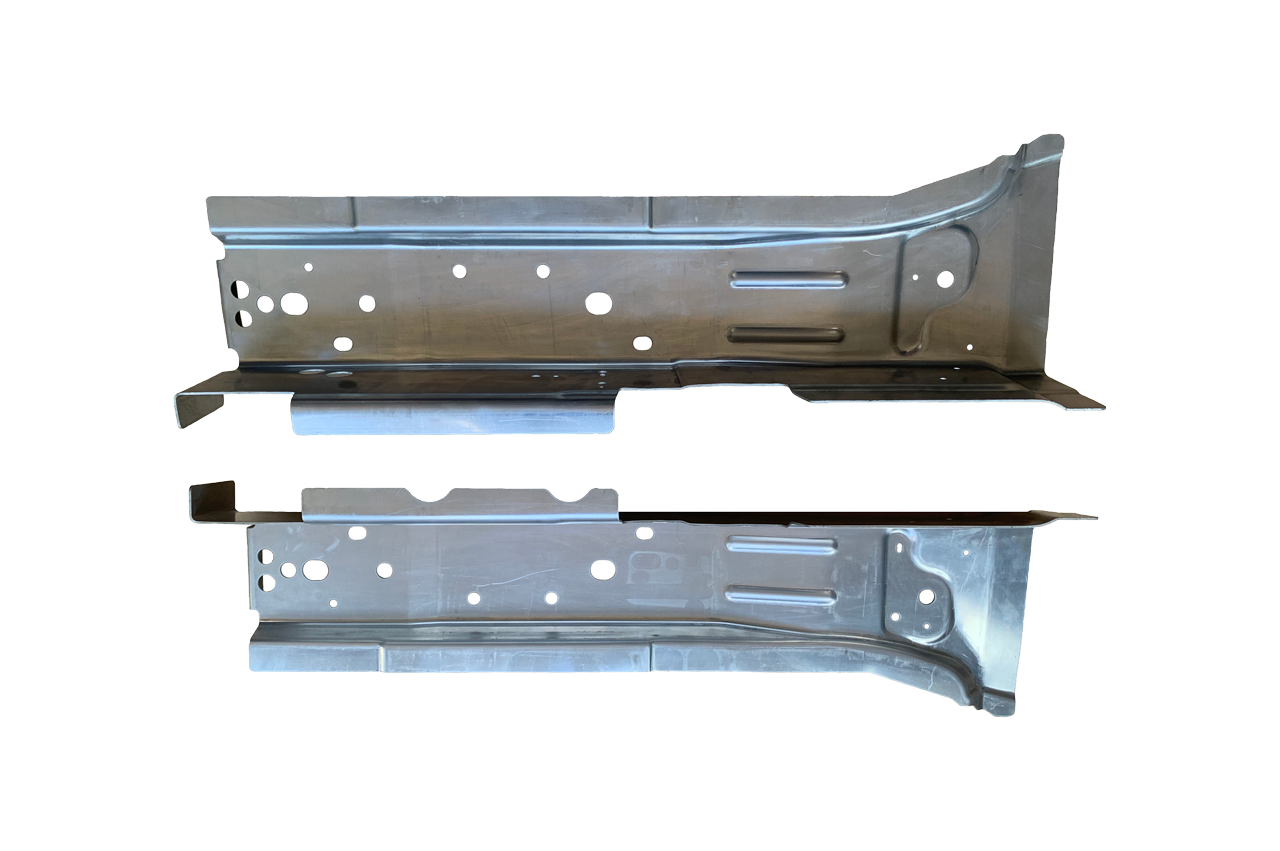

Member Floor Side Outer Rear Part

Part Name:

Member Floor Side Outer Rear RH/LH

Material Grade: AC300

Material Size: 2.50mm x 1000mm x 816mm

Stage Process: 600T PRG Blank & x 5 Stage 2500T TRF

Cavity: R and L parts out

Press Machine: 1200T Mechanical, 2000T press

Inspection Tool: Checking fixture, Laser scan, CMM

Lead Time: 6 months

Technical Key Point: Surface deformation issue

Background:

In the process of flange and restrike often appear parts of the deformation phenomenon, in the non-surface parts generally will not have much impact on the quality of the parts, but in the surface parts, as long as there is a little deformation will bring great quality defects to the appearance, affecting the quality of the vehicle.

There are two reasons why part will occur deformation issue, one is that stamping parts in the forming and flange stages, sheet deformation and flow, if the pressure is not tight will cause deformation. The other one is in the case of large enough pressing force, if the pressing surface is not uniform, there is a local gap, the above situation will also occur.

Due to this, increase the pressing force, if it is a spring pressing material, spring can be added, on the air cushion pressing material is usually used to increase the air cushion force. If the pressure is increased, there is deformation in the local, can use red lead to find out the specific problem point, check whether the pressing surface is local depression and so on, at this time can be used to weld the pressing plate method. After welding, the pressing plate is grinded and matched with the lower surface of the tool.

If you have interest or want to know more about aluminum part deformation how to solve, please do not hesitate to contact us. We are pleased to discuss with you.